About Us

Dongguan Zelv Electronic Technology Co., Ltd. is a professional manufacturing-oriented enterprise specializing in the research, development, production, and global supply of intelligent construction and photovoltaic equipment. Founded in 2019, Zelv is headquartered in Dongguan, China—one of the country’s most important manufacturing and innovation hubs. After years of steady development, the company has grown into a mature factory with approximately 50 skilled employees, integrating product design, manufacturing, quality control, and after-sales service under one roof.

From the very beginning, Zelv has adhered to the philosophy of “Technology-driven manufacturing, quality-first delivery, and customer-oriented service.” Our core product lines include solar panel cleaning robots and cleaning brushes, solar panel lifting machines, electric scaffolding lifting machines, casting machines for Roman columns, and automatic plastering machines. These products are widely used in photovoltaic power plants, construction sites, building renovation projects, rural housing construction, and industrial maintenance scenarios. Today, Zelv products are sold not only throughout the domestic Chinese market but also exported to Southeast Asia, the Middle East, Africa, Europe, Australia, and South America, earning long-term trust from distributors, contractors, EPC companies, and end users worldwide.

As a source manufacturer, Zelv operates its own production workshops, assembly lines, testing facilities, and warehouses. This allows us to strictly control product quality, shorten delivery time, and provide competitive factory-direct pricing. With a stable supply chain, sufficient stock for hot-selling models, and flexible OEM/ODM capabilities, we are able to respond quickly to market demand and support customers at every stage—from product selection and customization to logistics and after-sales service.

Product Portfolio and Key Advantages

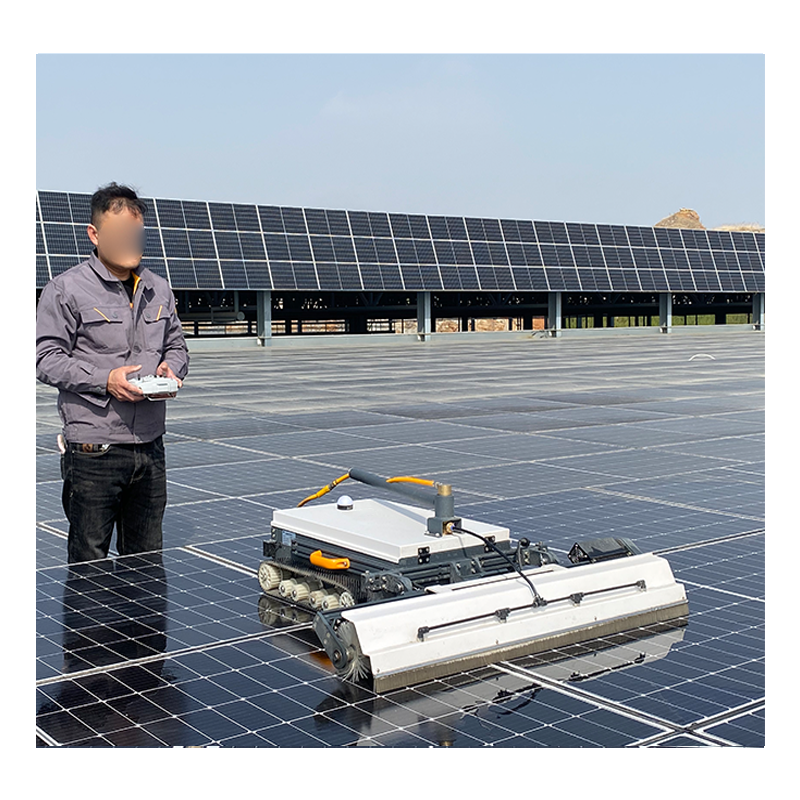

1. Solar Panel Cleaning Robot

Zelv solar panel cleaning robots are designed to maximize cleaning efficiency while minimizing labor cost and operational risk. With a daily cleaning capacity of 2–3 MW, the robot significantly improves the operation and maintenance efficiency of photovoltaic power plants. It supports both dry cleaning and water cleaning, making it suitable for various environments such as deserts, coastal areas, and industrial zones.

The robot can operate on solar panel arrays with a maximum slope of up to 15° and can be controlled remotely from a distance of up to 150 meters, ensuring safe and flexible operation. Equipped with high-quality nylon brushes, it effectively removes dust, sand, bird droppings, and stubborn stains without damaging the panel surface. The system is powered by dual high-capacity lithium batteries, enabling up to 8 hours of continuous operation on a single charge.

As a factory-direct supplier, Zelv ensures reliable after-sales service, sufficient inventory, and fast delivery. Most models are available in stock, allowing same-day packing and shipment once payment is confirmed, helping customers minimize downtime and accelerate project schedules.

2. Solar Panel Cleaning Brush

The Zelv Solar Cleaning Brush is a lightweight, efficient, and easy-to-use solution for manual photovoltaic cleaning. Designed for flexibility and portability, it supports both dry and wet cleaning, making it ideal for rooftop systems, distributed PV installations, and small to medium-scale solar plants.

The Zelv solar cleaning brush features a telescopic pole adjustable from 3.5 meters to 7.5 meters, allowing operators to easily reach both high and low panel rows. The pole is lightweight yet robust, reducing operator fatigue during long cleaning sessions. A 150W DC motor delivers strong and stable power, achieving a rotation speed of 700 RPM, ensuring fast and thorough cleaning performance.

The 60 cm anti-aging nylon brush head is highly durable, with a service life of over five years under normal use. As a source factory, Zelv offers direct supply, stable quality, and fast shipping. With ready stock available, orders can be shipped within 24 hours after payment, helping customers respond quickly to project needs.

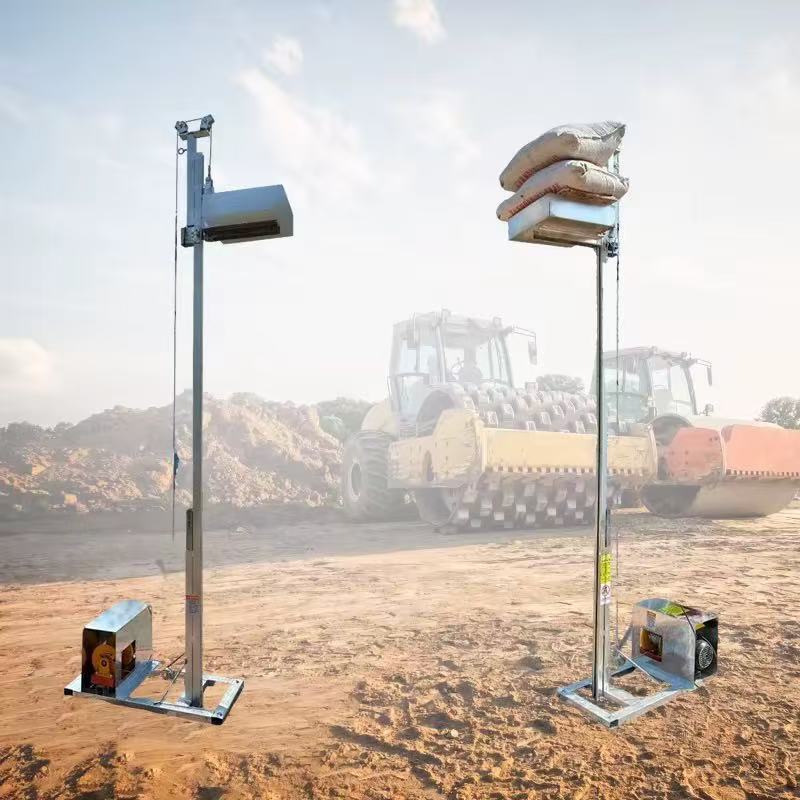

3. Solar Panel Lifting Machine

Zelv solar panel lifting machines are designed to improve efficiency and safety in photovoltaic installation and construction material handling. Featuring fast lifting speed and simple installation, one operator can complete lifting tasks that would normally require three workers, significantly reducing labor costs.

Powered by a second-generation high-performance electric motor, the lifting machine offers strong and stable output with a maximum load capacity of 300 kg. The lifting height is adjustable and customizable, ranging from 4 meters up to 30 meters, making it suitable for various building heights and project requirements.

This machine is widely used for lifting solar panels, glass, tiles, doors, windows, lighting fixtures, and other building materials. With sufficient inventory and efficient logistics, Zelv ensures fast delivery to meet tight construction schedules.

4. Electric Scaffolding Lifting Machine

The electric scaffolding lifting machine is a versatile solution for construction sites, interior decoration projects, and exterior cleaning operations. It features wireless remote control, allowing users to raise or lower the platform with one-button operation, eliminating the need for traditional scaffolding assembly and saving significant time and labor.

Safety is a top priority in its design. The structure is reinforced with six solid steel pipes and galvanized steel wire ropes, combined with upper and lower limit protection systems to ensure secure operation. A durable traditional electric motor provides stable performance, while universal wheels with brakes allow smooth movement and secure positioning.

Made with national-standard steel pipes, the platform supports a load capacity of 300–500 kg. The lifting height ranges from 2 meters to 12 meters, making it suitable for a wide range of construction and maintenance applications.

5. Roman Column Casting Machine

Zelv Roman column casting machines are designed to save time, labor, and manpower in rural housing and building construction. This electric concrete casting machine offers an impressive lifting speed of 70 meters per minute and can be assembled in just three minutes, ensuring quick setup on site.

With a load capacity of up to 100 kg, the machine enables easy concrete feeding and stable operation. It runs on standard 220V household electricity and is equipped with a 2400W pure copper motor, delivering reliable power and long service life. This machine is widely used for Roman column casting, concrete feeding, and small-scale construction projects.

6. Automatic Plastering Machine

The automatic plastering machine (also known as an auto plaster machine or wall rendering machine) is an advanced construction automation solution designed to improve wall plastering efficiency and quality. It is primarily used to evenly apply cement or mortar to interior walls, completing leveling and plastering processes with high precision.

Key features include automated material feeding, plastering, and surface finishing, significantly reducing labor intensity compared to traditional manual methods. The machine offers high efficiency, typically completing dozens of square meters per hour, greatly shortening construction timelines.

Through mechanical control, the plastering machine ensures consistent wall flatness, verticality, and uniform thickness, avoiding common manual issues such as uneven surfaces. Operation is simple and usually requires only one worker, who can control lifting and movement through a user-friendly control panel.

Working Principle:

• Feeding: Mixed mortar is poured into the hopper at the base of the machine.

• Plastering: The internal conveying system transports the mortar to the plastering board and applies it evenly to the wall.

• Leveling: The plastering and scraping boards perform preliminary leveling.

• Lifting and Moving: After finishing one wall section, the height can be adjusted or the machine moved to the next working area.

Our Commitment

At Dongguan Zelv Electronic Technology Co., Ltd., we believe that high-quality products are the foundation of long-term cooperation, and professional service is the bridge to customer success. We are committed to continuous innovation, strict quality control, and responsive after-sales support. By working closely with our customers, understanding their real project needs, and delivering reliable solutions, we strive to grow together and create shared success in the global market.

We warmly welcome partners from around the world to cooperate with Zelv and build a stronger, more efficient future together.